Timber Sports Floor

Resilient™ Timber Sports Floor System are constructed using either hardwood timber parquetry fingers or tongue and groove strip timber boards. The timber parquetry shall be fully bonded to the plywood subfloor, laid at 45 degrees to the direction of the plywood.

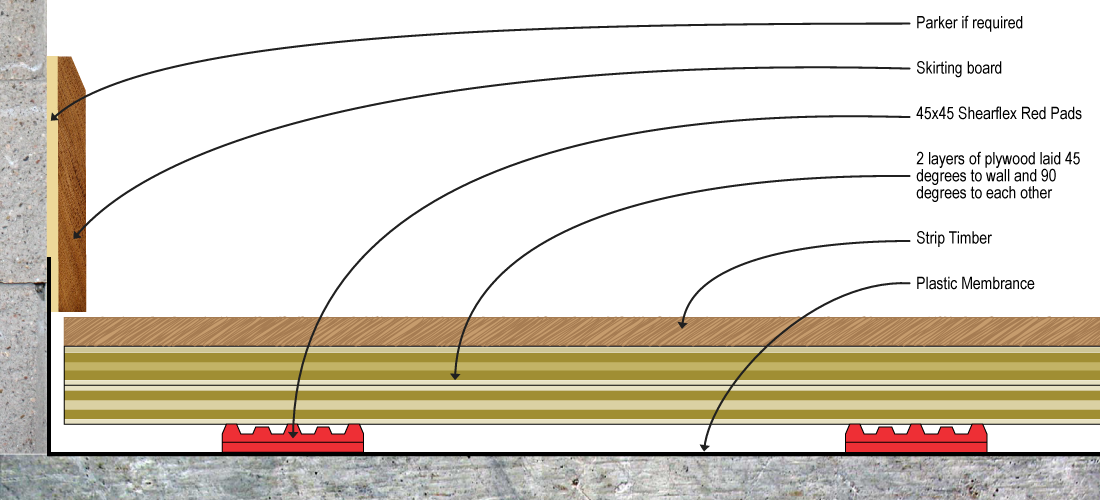

The timber floor surfacing materials shall be fully supported over the entire area to be covered by a double layer of MR grade 12mm thick plywood. Individual elastomeric pads of approved dimension and hardness shall support the plywood layers over the entire area to be covered, with special attention given to the perimeters of the installation. The flooring system shall be isolated from the substrate with a minimum 200um polyethylene sheeting lapped and taped at all joints.

The timber floor surface species recommended include Merbau, Kempas and White Oak (The parquetry will be of Merbau or Kempas species). Other timbers may be suitable for this system.

Junckers Sports Lacquer

Approved according to EN14904

Junckers is represented at many indoor sporting events around the world. Junckers has a complete programme that can provide durability and lining for sports floors. And one can certainly say that Junckers shines up the floor. Both before and after the game.

Junckers HP SPORT Lacquer can withstand all hard sports tackles and it is quick and easy to machine clean, so that the floor is ready for new challenges.

World leading sports lacquer (Approved according to EN14904)

Junckers is Europe’s leading manufacturer of solid hardwood sports, dance and activity floor systems. For many decades Junckers has provided systems to meet the wide ranging needs of local community and multi purpose halls, through to global landmark venues for Olympic, Commonwealth and professional sport.

Here the Reference

Junckers prefinished sports floors are very wear-resistant, however maintaining the floor on a regular basis contributes to sustaining a long life span. Daily care is done by sweeping or vacuuming, but when necessary the surface is easily renewed by a light sanding and then applying one coat of Junckers own produced water-based sports lacquer.

Asia & Pacific

Yuen Long Area 13 School

Hong Kong, Hong Kong

2,800 sqm.

Kowloon Park Redevelopment

Hong Kong, Hong Kong

1,967 sqm.

Tung Chung IRC

Hong Kong, Hong Kong

2,200 sqm

St. Paul Co-ed College Primary School

Hong Kong, Hong Kong

1,500 sqm.

Guangzhou Tianhe Gymnasium

Guangzhou, China

2,300 sqm.

Beijing Sports University

Beijing, China

12,000 sqm (3 sportshalls)

Taipei Municipal Nei-Hu High School

Taipei Nei-Hu, Taiwan

1,186 sqm.

Taipei County Yingge Vocational High School

Taipei County Yingge, Taiwan

1,106 sqm.

Beijing Sports University

Beijing, China

12,000 sqm (3 sportshalls)

Beijing Sports University

Beijing, China

12,000 sqm (3 sportshalls)

Porirua Sports and Events Centre

Wellington, New Zealand

3,400 sqm.

Arena Manawatu

Palmerston, New Zealand

2,500 sqm.

Saxton Indoor Sports Stadium

Nelson, New Zealand

3,800 sqm.

Waitekere Stadium

Auckland, New Zealand

5,800 sqm.

Europe + Russia (CIS)

Frankfurt Halle

Frankfurt, Germany

1,400 sqm.

Campushalle Flensburg

Flensburg, Germany

1,000 sqm.

Cesis Arena

Cesis, Latvia

2,100 sqm.

Sporthalle Grundschule Mejasi

Split, Croatia

1,450 sqm.

University of Cyprus

Nicosia, Cyprus

1,500 sqm.

Latsia Gymnasium

Nicosia, Cyprus

1,600 sqm.

Gigantium

Aalborg, Denmark

1,000 sqm.

NRGI Arena

Aarhus, Denmark

1,200 sqm.

Odense Kongrescenter

Odense, Denmark

3,000 sqm.

KEF-Centret

Kolding, Denmark

1,100 sqm.

Glasgow Commonwealth Games 2014

Crystal Palace Sports Centre

London, England

2,500 sqm.

London School for Contemporary Dance

The Place, London, England

1000 sqm.

NIKE Regal Sports Centre

London, England

600 sqm.

Guildford Spectrum Leisure Ctr. Sports Hall

Guildford, England

670 sqm.

Dojo of Ceyrat

Ceyrat Department 63

Ceyrat, France

2,452 sqm.

Rink Hockey Sport Room

Auxerre Department 89

Auxerre, France

1,803 sqm.

UCC Mardyke Arena

Main Sports Hall, Cork

Cork, Ireland

1,080 sqm.

Killarney Sports & Leisure Complex

Main Sports Hall, Kerry

Kerry, Ireland

1,200 sqm.

Siemens Arena

Vilnius, Lithuania

615 sqm.

Lietuvos Ryto Arena

Vilnius, Lithuania

600 sqm.

Helenic Arena

Athens, Greece

1,800 sqm.

Jalilabad Olympic Sport Complex

Jalilabad, Azerbaijan

1300 sqm.

Spodek Sports Hall

Katowice, Poland

1,750 sqm.

Mosir Lodz

Poland

2,300 sqm.

Adam Mickiewicz University

Poznan, Poland

1,600 sqm.

Ustrzyki Dolne Sports hall

Poland

1,100 sqm.

Biala Multipurpose Sports hall

Poland

1860 sqm

Biala Multipurpose Sports hall

Poland

1860 sqm.

Polivalenta Arena

Bucharest, Romania

1,200 sqm.

CSKA Moscow Basketball Club

Moscow, Russia

850 sqm.

Sports Complex Gazprom Neft

Saint Petersburg, Russia

775 sqm.

Sports School of Olympic Reserve

Moscow, Russia

750 sqm.

Sports Palace

Tbilisi, Georgia

1,400 sqm.

Primary School, Dusan Radovic

Nis, Serbia

1,000 sqm.

Belgrade Arena

Belgrade, Serbia

1800 sqm.

Aréna Poprad

Poprad, Slovakia

1,550 sqm.

Mestská Hala

Presov, Slovakia

1,727 sqm.

Športová hala Pasienky

Bratislava, Slovakia

1,000 sqm.

Palacio de Los Deportes Santa Cristina

Torrevieja (Alicante), Spain

3,151 sqm.

Agrupacion Deportiva San Juan

Pamplona, Spain

1,673 sqm.

Middle East

Cairo Stadium Squash Center

Nasr City, Cairo, Egypt

320 sqm.

Mashhad University

Mashhad, Iran

2,800 sqm.

Al Oyoun Club, Kuwait Olympic Committee

Gahra, Kuwait

1400 sqm.

19th Arabian Gulf Cup

SQSC-Bowsher, Muscat, Sultanate of Oman

608 sqm.

Masdar City Sports Hall

Abu Dhabi, UAE

1394 sqm.

American School Sports Hall

Dubai, UAE

1200 sqm.

USA + South America

Cal State University of Long Beach

Long Beach, California

3,300 sqm.

Southwest College

California

1,000 sqm.

Dancing With The Stars Show

California

200 sqm.

Torah Academy

New York

1,000 sqm.

Arcadia High School

California

1,800 sqm.

Hooptown

Tennessee

1,200 sqm.

City of Kingsport

Tennessee

1,200 sqm.

Speyer Legacy School

New York

600 sqm.

Pacific Grove Middle School

California

600 sqm.

Gimnasio Goodness

Los Angeles, Chile

133 sqm.

OLYMPIC STADIUMS

Russia

Kazan Universiade, 2013

10,000 sqm.

United Kingdom

Olympics London, 2012,

Handball Court

3,000 sqm.

Singapore

Singapore Youth Olympics, 2010

Portable Flooring

1,000 sqm.

China

Beijing Youth Olympic Games, 2009

Portable Flooring

4,500 sqm.

China

Beijing Olympic Games, 2008

12,000 sqm. Flooring

Greece

Olympics Athens, 2004

.. and countless more all over the world

Floor Safety and Performance

The standard relates to both safety and sports technical properties and the most important key factors are described below.

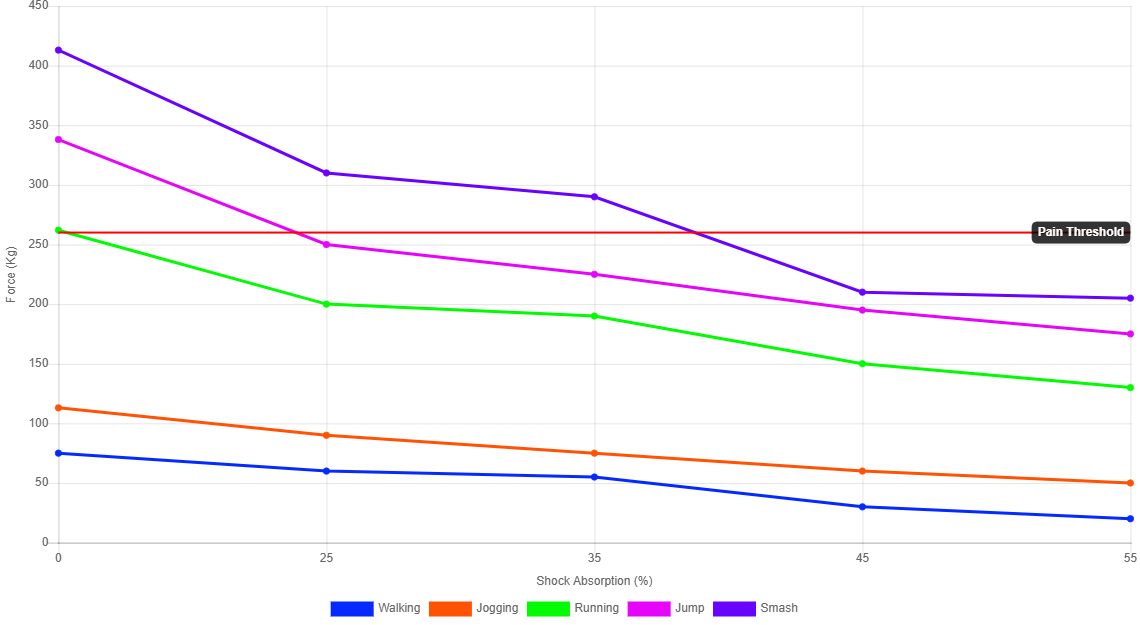

Shock Absorption

A shock-absorbing floor minimises the risk of injuries. Shock energy is absorbed by the floor when landing after a jump, the balance will be reflected on the legs and body of athletes.

Vertical Deformation

The floor’s ability to absorb shock depends on its ability to flex when exposed to a dynamic load. Test results display the floor’s vertical deformation in mm when exposed to a dynamic impact equivalent to that of light jogging.

Ball Bounce

The floor’s ability to absorb shock depends on its ability to flex when exposed to a dynamic load. Test results display the floor’s vertical deformation in mm when exposed to a dynamic impact equivalent to that of light jogging.

Friction

Correct friction is important when ball players move rapidly on the floor, and the ideal friction rating is between 80 and 110. A friction value less than 80 makes the floor too smooth, and above 110 makes the floor too rough.

Rolling Load

The floor’s ability to withstand rolling loads is important for example where trolleys and retractable seating are used. Test results display whether the floor can withstand a rolling load of 1,500 N (approx. 150 kgs).

Timber Floating Floor Isolation

Shearflex and Supershearflex

Application

Shearflex and Supershearflex are shock pads for use in sports flooring or as an acoustic isolation pad underneath battens and timber strip flooring in apartments. They are also commonly used in theatres and auditoriums where moderate acoustical performance is required.

Features

- Unloaded thickness: 10.5mm – Shearflex, 17mm – Supershearflex

- Cross-ribbed, non-skid faces which usually eliminate the need for bolting down

- Alternately raised ribs

- May be used in multiple layers with steel or aluminium shim spacers to increase isolation efficiency

- Available in a variety of load ratings

Pain Threshold vs Shock Absorption

EN14904 Standard

Minimal performance requirements to be met by indoor sports floors.

Installation – Sports Floors / Auditoriums

2 Layer"Plank-on-Ply"

Lay 100μm plastic membrane across entire floor with 100mm overlaps on joints and extending 100mm up each wall. Using a template, fix 45x45mm Shearflex red pads to first sheet of 12mm ply at 300x300mm centers.

Turn the plywood over and lay sheets at 45 degrees diagonally across the room leaving an expansion gap along the perimeter of 1.5mm per metre of floor between wall and floor. Always leave 2mm gaps between adjoining sheets.

Second sheet should be tack nailed and glued to the first sheet at 90 degrees to the first sheet, again leaving 2mm gap between sheets.

Install the final floor covering which may be either strip timber or mosaic parquetry. Strip timber is normally secret nailed while parquetry is glued using a timber flooring adhesive.

After the floor is sanded and finished, install skirts to perimeter.

Standard Values

The EN 14904 standard determines force reduction classes for all floors. The objective is to draw attention to the necessity of installing safe, comfortable floors that reduce the risk of injuries.

Sports Properties

| DESCRIPTION | STANDARD | REQUIREMENT | UNITS | RESILIENT TIMBER |

|---|---|---|---|---|

| Vertical deformation | EN 14809 | ≤ 3.5 | mm | Pending |

| Shock absorption (Force Reduction) | EN 14808 | ≥ 25 | % | Pending |

| Friction coefficient | EN 13036-4 | 80 - 110 | - | Pass SIRIM Test |

Technical Characteristics

| DESCRIPTION | STANDARD | REQUIREMENT | UNITS | RESILIENT TIMBER |

|---|---|---|---|---|

| Ball bounce | EN 12 235 | ≥ 90 | % | Pending |

| Indentation resistance | EN 1516 | ≤ 0.5 | mm | Pass SIRIM Test |

| Wheel resistance | EN 1569 | ≥ 1500 | N | Pending |

| Impact resistance | EN 1517 | ≥ 8 | N/m | Pass SIRIM Test |

| Abrasion resistance | EN ISO 5470-1 | ≤ 1000 | mg | Pass SIRIM Test |

| Gloss | EN ISO 2813 | ≤ 30 | % | Pending |

| Flatness | EN 13036-7 | < 6mm/3m | - | Pending |

Classification

| DESCRIPTION | STANDARD | REQUIREMENT | UNITS | RESILIENT TIMBER |

|---|---|---|---|---|

| Fire rating | EN 13501-1 | Cfl-s1 | - | Pending |

| Formaldehyde emission | EN 717-1/2 | ≥ E1 | - | Pending |

| Flatness | EN 13036-7 | < 6mm/3m | - | Pending |